Car Insulation Case Study- Automotive Sound Insulation

Case Study: Solving Heat Insulation Challenges in the Automobile Sector with E-Glass Needle Mat

Problem

A major automotive manufacturer faced persistent challenges with heat insulation and noise reduction in their vehicles, especially in cars. Their vehicles were experiencing the following issues:

High Cabin Temperatures

Excessive heat transfer from the engine and exhaust system was raising cabin temperatures, impacting passenger comfort.

Noise Pollution

Engine vibrations and road noise were creating an unpleasant experience for passengers.

Weight Management

Existing insulation materials were bulky and added significant weight, affecting fuel efficiency and vehicle performance.

Durability Issues

Prolonged exposure to high temperatures was degrading traditional insulation materials, increasing maintenance costs.

Solution

Adoption of E-Glass Needle Mat

The manufacturer adopted E-Glass Needle Mat, a high-performance insulation material composed of fine glass fibers mechanically bonded into a mat. It provided the following benefits:

Superior Thermal Insulation

E-glass has excellent heat resistance, withstanding temperatures up to 750°C without losing structural integrity. This reduced heat transfer into the cabin significantly.

Sound Absorption

The mat’s porous structure absorbed engine vibrations and road noise, enhancing the acoustic experience.

Lightweight Design

Being lightweight yet durable, it improved vehicle efficiency without compromising insulation performance.

Chemical Resistance

Resistant to oil, moisture, and other automotive fluids, the mat ensured durability in harsh environments.

Eco-Friendly Manufacturing

Made from non-toxic, recyclable materials, the E-glass needle mat aligned with the manufacturer’s sustainability goals.

Implementation

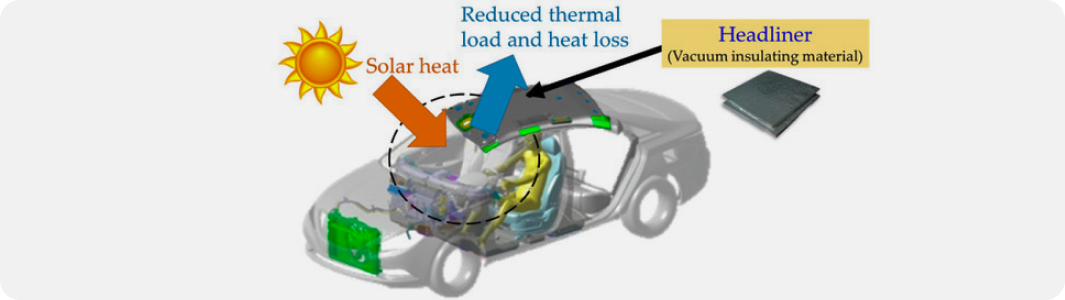

Application Areas

The E-glass needle mat was used in:

- Engine compartments

- Exhaust systems

- Underbody panels

- Door interiors and roof liners

Installation Process

The mats were cut and shaped to fit the specific contours of the vehicles and adhered using heat-resistant adhesives.

Outcome

After implementation, the automotive manufacturer reported the following improvements:

Cabin Comfort

Cabin temperatures dropped by 30%, enhancing passenger comfort.

Noise Reduction

Noise levels inside the vehicle decreased by 25%, significantly improving the ride experience.

Weight Savings

Overall vehicle weight reduced by 10%, leading to a 5% improvement in fuel efficiency.

Cost Efficiency

The durability of the E-glass needle mat lowered replacement and maintenance costs by 15% annually.

Conclusion

E-glass needle mats proved to be a game-changer in addressing heat and noise challenges in the automotive sector. By integrating this advanced material, the manufacturer not only enhanced product quality but also achieved sustainability and performance goals. This case highlights the potential of E-glass needle mats as a critical solution for modern automotive insulation challenges.