XLPE

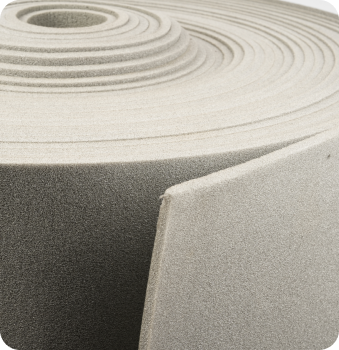

XLPE (Cross-linked Polyethylene) Foam Insulation

XLPE (Cross-linked Polyethylene) Foam is a high-performance, closed-cell, lightweight insulation material created through a chemical or physical cross-linking process. This unique structure provides an excellent thermal barrier, superior moisture resistance, and outstanding flexibility, making it the ideal choice for insulating HVAC systems, chiller pipelines, and cold-storage units. We specialize in providing a full range of non-fibrous XLPE products, including Class O rated variants for fire-safety critical applications.

Products

We offer a diverse range of XLPE insulation products in various forms, densities, and facings to meet the stringent requirements of commercial and industrial projects.

- AEROLAM XLPE FLEXI CLASS O

- XLPE ONE SIDE FSK CLASS-0

- XLPE ONE SIDE ALU. FOIL - CLASS 0

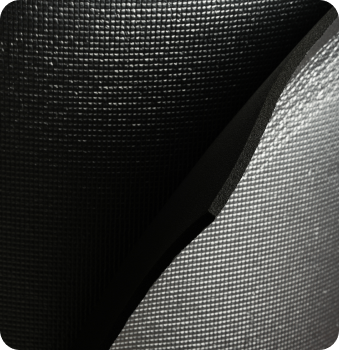

- AEROLAM CLASS O WITH BLACK FLEXI ALUPET

- XLPE - 9MM THICK PLAIN

Detailed Information

Key features

XLPE foam’s closed-cell structure delivers essential performance benefits that contribute to energy efficiency and long-term system integrity.

- Excellent Water & Vapor Barrier:

The closed-cell structure acts as an internal vapor barrier, preventing condensation (sweating) and eliminating the need for an external vapor retarder.

- Low Thermal Conductivity:

Ensures a very low heat transfer rate, maximizing thermal efficiency and reducing operational energy costs for cooling and heating.

- Class O Fire Rating:

Many variants are formulated to meet the Class O fire standard, offering high fire resistance and low smoke emission for enhanced safety.

- Flexibility & Ease of Installation:

Highly flexible and lightweight, making it easy to cut, shape, and install on complex shapes and tight areas, minimizing installation time and waste.

- Durable & Chemical Resistant:

Resists chemicals, fungal growth, and abrasion, ensuring a long service life and low maintenance.

- Non-Fibrous & Non-Porous:

Ideal for applications where fiber shedding is a concern, such as clean rooms, hospitals, and food processing plants.

Applications

XLPE insulation is widely used in commercial, residential, and industrial construction, particularly in low-temperature and HVAC systems.

- HVAC Duct Insulation:

Used externally on supply and return air ducts to prevent thermal loss and condensation.

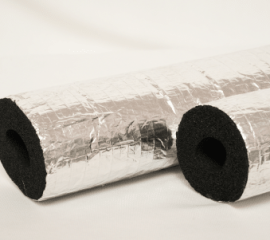

- Chilled Water and Refrigeration Piping:

Essential for insulating cold lines to maintain temperature and prevent pipe sweating.

- Cold Storage & Refrigeration Units:

Lining walls, ceilings, and floors in temperature-controlled warehouses and cold rooms.

- Clean Room Environments:

Chosen for its non-fibrous nature and fire safety compliance in pharmaceutical, microchip, and electronic manufacturing facilities.

- Acoustic Damping:

Can be used under screeds or within partitions for impact sound and vibration reduction.

Facing Options

The performance of XLPE is often enhanced with protective and functional facings.

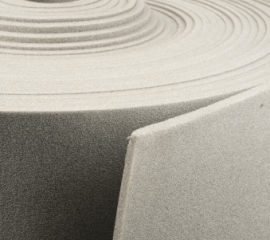

- Plain (Unfaced):

Used when the foam is enclosed, or for acoustic damping applications.

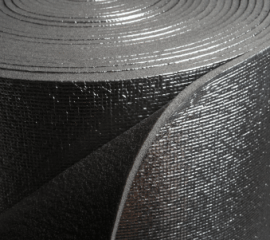

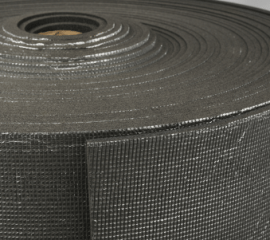

- Aluminum Foil (Alu Foil):

Provides a robust, reflective external vapor barrier and a neat finish.

- Aluminum Polyester (ALUPET):

A strong, multi-layered film offering superior vapor resistance and high aesthetic value.

- Glass Cloth (GC):

Offers excellent protection against mechanical damage and improved resistance to UV exposure.

- Self-Adhesive Backing:

Available for sheets and pipe sections to facilitate quick and secure installation.

Temperature Range

XLPE is primarily utilized in cryogenic and medium-temperature applications where its flexibility and closed-cell properties are vital

- Operating Temperature:

Typically suitable for continuous service from -40°C to +115°C (or higher depending on specific formulation).

- Cold Application Integrity:

Maintains superior thermal and mechanical properties down to cryogenic temperatures.

Size, Density & Thickness

We provide customizable dimensions to suit the exact requirements of any project specification.

- Density:

Available in densities typically ranging from 25 kg/m³ to 33 kg/m³, offering a balance of flexibility and structural integrity.

- Thickness (Sheets/Rolls):

Common thicknesses range from 6 mm up to 50 mm, supplied in rolls or sheets.

- Thickness (Pipe Sections):

Available in standard industry thicknesses (e.g., 9mm, 13mm, 19mm, 25mm) to match specific pipe sizes and insulation requirements.